Mike Elms, Technical Manager at KOHLER Uninterruptible Power Ltd, a KOHLER company, explains why sizing a UPS correctly for a specific site takes more than just a knowledge of the site’s kVA load requirement.

What is involved in sizing a UPS?

Superficially, sizing a UPS appears to be simple; add up the total kVA requirement of the critical load and allow for some spare capacity to arrive at the UPS’s kVA specification. Although this approach is certainly an essential starting point, there are other factors that must be understood and allowed for to establish the UPS’s true sizing requirement.

How do I find out what the actual load is?

Most electrical equipment items have labels displaying their electrical characteristics. This information can be collated, and should include required supply voltage, number of phases, load current, power factor and power consumption. The number of phases is important, because if any part of the critical load is three-phase then a three-phase UPS becomes essential. A three-phase UPS can, however, supply both single – and three – phase equipment items.

kVA ratings can be noted and totalled using an online tool such as the KUP kVA Load Calculator.

For a more accurate view of the actual load and how it varies over time, a site survey using portable measuring and monitoring equipment becomes vital. Many UPS suppliers offer this service, including KUP.

Why is the load’s power factor so important?

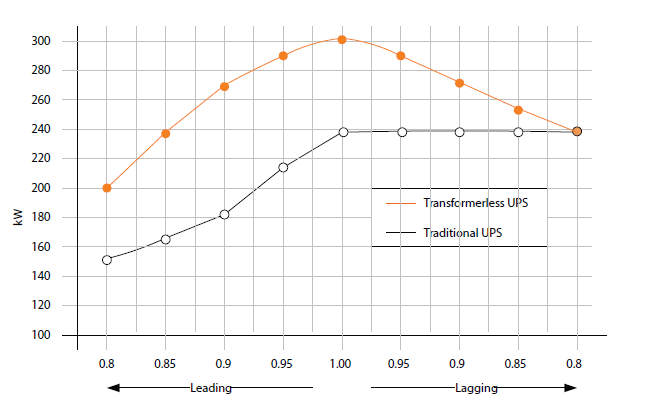

Historically, loads have tended to present an inductive or lagging PF, typically of around 0.8. The more recent shift to blade servers and other equipment using switched mode power supplies (SMPSs) has resulted in load PFs approaching unity or even becoming capacitive or leading. Legacy transformer-based UPSs derate substantially under these conditions, while modern transformerless types are less affected. Fig. 1 below shows the impact of PF on both UPS topologies. Note that modern transformerless UPS, in this example, need no derating at unity PF; the 300kVA system can deliver full 300 kW power while the transformer-based equivalent is limited to 240 kW.

Fig.1: Impact of power factor on UPS derating

What equipment-related problems am I likely to encounter?

Increasing SMPS efficiency has created increased harmonic content in the load. All computer power supplies must have at least passive power factor correction to comply with EU standard EN61000-3-2. Equipment that imposes harmonic distortion can also create other problems such as high or pulsed currents during normal operation or start-up. Known ‘problem’ equipment in this area includes laser printers and some types of lighting.

Why is phase-balancing important – and why isn’t it straightforward?

For three-phase UPSs, balancing the load across all phases is important to ensure that the UPS’s rating is fully utilised, as well as presenting a balanced load to the mains or generator if the UPS is bypassed. Most modern UPSs do not require careful phase balancing to operate correctly; even so, the load on any single-phase must never exceed 33% of the UPS’s total rating.

Computer network equipment can create very high currents in the neutral conductor of a three-phase Y power distribution system even if the loads are apparently balanced. This problem typically occurs when single-phase computer units with non-linear load characteristics are connected across line L1, L2 or L3 and neutral. High neutral currents can cause overloading of feeders and transformers as well as voltage distortion and common-mode distortion.

Any other problems I should allow for?

Some equipment such as motors can cause problems through inrush current as well as the harmonic distortion mentioned above. If such devices lack soft-start circuits, they can draw up to 15 – 20 times their steady-state current, as Fig. 2 shows. Significant oversizing of the UPS is required to support these high-inrush loads.

Fig. 2: Typical computer in-rush current

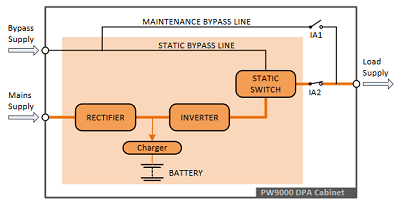

How does the UPS’s topology affect its sizing?

As we have seen, UPS topology is important, because transformer-based types are so much more adversely affected by poor power factor loads than their modern transformerless equivalents. However, modular transformerless installations offer future-proofing benefits too; because additional modules can so easily be plugged in to the UPS frame as need arises. This means UPSs do not have to be excessively oversized during initial installation but are adaptable to cope with future power demands.

Incrementing UPS capacity using small modules allows accurate UPS sizing even with built-in redundancy. For example, a load requirement for 120kVA with redundancy could be satisfied with two transformer-based units of 120kVA each in a 1+1 redundant configuration. However, this represents 50% excess capacity, while the lightly-loaded transformer-based UPSs operate at low efficiency. By contrast, the 120kVA redundant requirement could be fulfilled by using four 40 KVA modules; this provides full load support with n+1 redundancy, while operating at high efficiency and only 40kVA extra capacity.

Is the UPS’s sizing affected by its application?

In some applications, the UPS may simply be required to support a safe system shutdown if the power fails. Other users will expect the UPS to maintain power throughout an extended blackout, allowing its load to remain in service. These diverse demands on autonomy will affect the size of the battery needed, possibly increasing the UPS’s overall footprint.

In summary

There are many factors to consider when sizing a UPS accurately for your particular site conditions. A knowledge of the critical load’s total kVA requirement, although essential, is not sufficient. The topology of the UPS itself can affect the sizing requirement, as can the electrical environment in and around the target site. Current and future expectations of the UPS’s role must also be taken into account to ensure that the UPS is correctly sized and future-proofed.